The plastic manufacturing industry is a complex and competitive sector that requires advanced systems to ensure smooth operations, minimize costs, and enhance overall productivity. From managing raw materials to production scheduling, quality control, and distribution, plastic manufacturers need comprehensive software solutions to optimize every aspect of their business.

Alwajeez Tech offers the best ERP software for plastic manufacturers, providing a tailored, integrated solution to streamline operations, improve decision-making, and drive profitability. This article explores the power of Alwajeez Tech ERP for plastics, its features, and how it helps businesses in the plastic manufacturing industry achieve greater efficiency, cost savings, and customer satisfaction.

Why Plastic Manufacturing Companies Need ERP Software

The plastic manufacturing industry faces a variety of challenges, such as fluctuating raw material costs, production inefficiencies, quality control issues, and complex supply chain management. Managing these challenges requires a unified system that integrates all departments, from production planning to sales and inventory management.

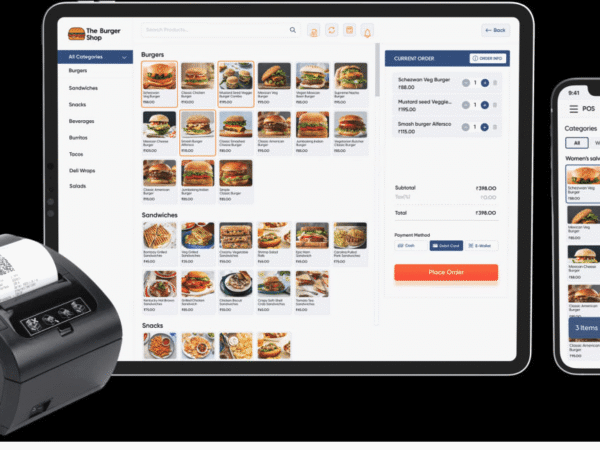

ERP software for plastic factories consolidates business operations into a single platform, improving efficiency and providing real-time data for better decision-making. By automating processes such as procurement, production scheduling, inventory control, and customer relationship management, ERP systems help plastic manufacturers reduce costs, improve product quality, and gain a competitive advantage in the market.

Alwajeez Tech offers a comprehensive plastic production ERP solution that addresses the unique needs of the plastic industry, improving everything from production planning to supply chain management.

Key Benefits of Alwajeez Tech ERP for Plastic Manufacturing

1. Increase Plastic Production with ERP

For any plastic manufacturing company, maximizing production efficiency is key to meeting customer demand and improving profitability. Alwajeez Tech ERP for plastic industry helps companies optimize production planning and resource allocation. The system offers advanced scheduling tools that ensure the production process runs smoothly and efficiently. By tracking machine performance and production status in real-time, manufacturers can reduce downtime, increase throughput, and increase plastic production with ERP.

2. Reduce Plastic Manufacturing Costs

With rising material costs and operational overheads, plastic manufacturers need to identify ways to reduce expenses without compromising product quality. Alwajeez Tech ERP solutions for plastics provide detailed cost tracking for every stage of the manufacturing process. From raw material procurement to energy usage and labor costs, the ERP system allows businesses to monitor and control costs effectively. This visibility helps companies reduce plastic manufacturing costs, identify inefficiencies, and ultimately boost profitability.

3. Improve Inventory Management for Plastics

Managing raw materials, work-in-progress items, and finished goods is challenging in plastic manufacturing. Overstocking can tie up valuable resources, while stockouts can delay production schedules. Alwajeez Tech plastic ERP enables improved inventory management for plastics by providing real-time tracking of inventory levels and automated reordering. The system ensures that businesses maintain the optimal stock levels, minimizing the risk of production delays and reducing carrying costs.

4. Enhance Plastic Quality Control

Plastic manufacturers must adhere to strict quality control standards to meet customer expectations and regulatory requirements. Alwajeez Tech plastic manufacturing software incorporates robust quality control features, such as automated testing and inspection checks, ensuring that all products meet industry standards. The system provides insights into product defects and allows manufacturers to take corrective actions quickly. This helps enhance plastic quality control, reduce waste, and improve product consistency.

5. Boost Plastic Sales with ERP

A comprehensive ERP system helps improve the sales process by integrating production schedules with customer orders. Alwajeez Tech ERP for plastic companies provides features such as customer relationship management (CRM), order tracking, and invoicing. By improving communication between production teams and the sales department, manufacturers can meet customer demand more efficiently and deliver orders on time. This can lead to a boost in plastic sales with ERP, enhancing customer satisfaction and building long-term relationships.

6. Improve Customer Satisfaction in the Plastic Industry

In the highly competitive plastic manufacturing industry, customer satisfaction is critical. Customers expect timely deliveries, high-quality products, and consistent communication. Alwajeez Tech plastic ERP provides manufacturers with the tools to manage customer orders, track delivery schedules, and respond to inquiries in real-time. With better visibility into production and inventory, manufacturers can improve customer satisfaction by meeting delivery deadlines and ensuring product quality.

7. Gain a Competitive Advantage with Plastic ERP

In today’s competitive market, gaining a competitive edge requires a combination of operational excellence and strategic insights. Alwajeez Tech plastic ERP provides manufacturers with the data they need to make informed decisions. With real-time insights into production performance, inventory levels, and customer orders, manufacturers can optimize operations, respond to market demands faster, and gain a competitive advantage with plastic ERP.

8. Improve Supply Chain Management for Plastics

The supply chain in the plastic manufacturing industry is often complex, involving multiple suppliers, production facilities, and distribution channels. Alwajeez Tech plastic ERP software helps improve supply chain management for plastics by providing real-time tracking of orders, materials, and suppliers. The system can also help forecast demand and optimize procurement processes, ensuring that businesses have the right materials at the right time to meet production goals.

9. Streamline Plastic Production Processes

Plastic manufacturing involves several steps, such as material handling, production scheduling, and quality testing. Without an integrated system, it can be challenging to coordinate all these processes effectively. Alwajeez Tech plastic ERP streamlines production processes by automating workflows, providing real-time production status updates, and improving communication across departments. By streamlining these processes, manufacturers can reduce bottlenecks and ensure timely production.

10. Increase Plastic Production Visibility

Visibility into the production process is essential for identifying inefficiencies, tracking production progress, and making informed decisions. Alwajeez Tech plastic ERP provides manufacturers with detailed dashboards and reporting tools to monitor all aspects of production. With increased plastic production visibility, businesses can identify bottlenecks, adjust schedules as needed, and improve overall operational efficiency.

Why Alwajeez Tech is the Best ERP for Plastic Manufacturing Companies

1. Customizable and Scalable Solution

Every plastic manufacturing company has its unique processes, requirements, and challenges. Alwajeez Tech ERP for plastic companies is highly customizable, allowing businesses to adapt the software to their specific needs. Whether you’re a small, medium, or large manufacturer, the system can scale with your business, providing consistent performance and functionality as your operations grow.

2. Cloud-Based Flexibility

Cloud-based ERP solutions offer flexibility and accessibility, and Alwajeez Tech ERP solutions for plastics are no exception. The cloud deployment allows businesses to access the system from anywhere, enabling remote monitoring and management of operations. Cloud deployment also reduces the need for costly on-premise infrastructure and ensures that the software is always up to date with the latest features and security patches.

3. Integration with Other Systems

Plastic manufacturers often use a range of different software tools to manage different aspects of their business, such as accounting, customer relationship management, and manufacturing execution systems. Alwajeez Tech plastic ERP integrates seamlessly with other business systems, providing a unified solution that reduces data silos and improves communication between departments.

4. Advanced Analytics and Reporting

Alwajeez Tech plastic manufacturing software includes advanced analytics and reporting features, allowing manufacturers to track key performance indicators (KPIs), monitor production trends, and analyze financial performance. These insights enable businesses to identify opportunities for improvement, make data-driven decisions, and drive operational efficiency.

5. User-Friendly Interface

Alwajeez Tech ensures that its ERP system is intuitive and easy to use, with a user-friendly interface that simplifies daily operations. Employees can quickly learn how to navigate the system and perform tasks efficiently, reducing training time and improving productivity.

6. Dedicated Support and Training

Implementing an ERP system is a significant investment, and Alwajeez Tech offers comprehensive support and training to ensure that businesses get the most out of their ERP system. The company’s customer service team is available to assist with troubleshooting, and businesses can also access online training materials to help employees learn how to use the system effectively.

Choosing the Right ERP for Your Plastic Manufacturing Company

When selecting an ERP system, plastic manufacturers need to consider various factors, such as the system’s functionality, ease of use, scalability, and cost. Here are some tips for choosing the right plastic ERP software:

- Assess Your Needs: Identify your company’s specific requirements and select an ERP solution that addresses those needs.

- Evaluate Key Features: Look for features such as production planning, inventory management, quality control, and supply chain management.

- Consider Future Growth: Choose an ERP system that can scale with your business as it grows.

- Check Integration Capabilities: Ensure the ERP system can integrate with your existing software tools.

- Analyze ROI: Evaluate the potential return on investment by considering the time and cost savings the ERP system can provide.

In the plastic manufacturing industry, efficiency, cost control, and product quality are critical to success. Alwajeez Tech ERP for plastics provides a comprehensive, integrated solution to help businesses optimize their operations, improve decision-making, and gain a competitive advantage. With advanced features such as inventory management, production planning, quality control, and analytics, Alwajeez Tech plastic ERP helps manufacturers increase plastic production, reduce costs, and improve customer satisfaction.

If you’re looking for the best ERP software for plastic manufacturers, Alwajeez Tech offers a solution that is customizable, scalable, and equipped with the latest technology. Contact Alwajeez Tech for plastic ERP today and experience how their solutions can transform your business operations and take your manufacturing processes to the next level.

then 'Add to home screen'

then 'Add to home screen' then 'Add to home screen'

then 'Add to home screen'