Best ERP Software for Chemicals Manufacturers by Alwajeez Tech

In the modern era of industrial growth, chemical manufacturing companies need reliable, scalable, and efficient solutions to manage their complex operations. As these industries deal with diverse processes like raw material procurement, production, quality control, inventory management, and distribution, integrating an advanced ERP (Enterprise Resource Planning) system can streamline operations and ensure business success.

Alwajeez Tech, a leader in technology solutions, offers the best ERP software for chemical manufacturers, tailored to meet the unique demands of the chemical industry. This article will explore how Alwajeez Tech ERP for chemicals enhances manufacturing efficiency, reduces costs, and boosts overall productivity.

Why Do Chemical Manufacturers Need an ERP System?

The chemical manufacturing industry is highly complex, with processes that require precision and efficiency at every step. From sourcing raw materials to quality control and distribution, manufacturers are constantly faced with challenges such as inventory management, compliance issues, supply chain inefficiencies, and rising production costs. An ERP for the chemical industry helps address these issues by integrating various functions into a unified system, ensuring smoother workflows and improved decision-making capabilities.

Implementing an ERP solution like Alwajeez Tech ERP for chemical plants not only brings all operations under one umbrella but also enhances visibility, control, and collaboration across departments. These advantages lead to significant improvements in chemical production efficiency, inventory management, quality control, and more.

Key Benefits of Alwajeez Tech ERP for Chemical Manufacturing

1. Increase Chemical Production with ERP

One of the most important goals for any chemical manufacturing company is to boost production without sacrificing quality. Alwajeez Tech chemical manufacturing software offers tools for production planning, scheduling, and resource allocation, allowing manufacturers to optimize workflows and reduce downtime. By enabling real-time tracking of production processes, manufacturers can quickly address issues, improve throughput, and ultimately increase chemical production.

2. Reduce Chemical Manufacturing Costs

Cost control is critical in the chemical manufacturing sector. With fluctuating raw material prices and tight profit margins, companies need to monitor costs meticulously. Alwajeez Tech ERP solutions for chemicals allow for detailed cost tracking, including raw materials, labor, energy consumption, and overheads. By identifying inefficiencies and waste, chemical manufacturers can reduce chemical manufacturing costs and improve profitability.

3. Improve Inventory Management for Chemicals

Chemical manufacturers often face challenges in managing large inventories of raw materials, intermediates, and finished goods. Using Alwajeez Tech chemical ERP, businesses can track inventory in real-time, ensuring optimal stock levels, minimizing the risk of stockouts, and reducing excess inventory. This improves inventory management for chemicals, leading to smoother production processes and better cash flow.

4. Enhance Chemical Quality Control

Quality control is crucial in the chemical manufacturing industry, where even minor deviations can lead to costly defects or safety risks. Alwajeez Tech ERP for chemicals incorporates built-in quality control features, ensuring that products meet industry standards and regulations. By automating testing and monitoring, manufacturers can maintain high levels of product quality and comply with safety regulations, which leads to enhanced chemical quality control.

5. Boost Chemical Sales with ERP

A well-integrated ERP system allows chemical manufacturers to streamline order processing, improve customer service, and accelerate sales. Alwajeez Tech chemical ERP provides powerful CRM (Customer Relationship Management) features to track customer interactions, orders, and sales trends. By offering better visibility into customer needs and inventory availability, manufacturers can boost chemical sales with ERP, providing timely deliveries and better customer satisfaction.

6. Improve Customer Satisfaction in the Chemical Industry

Customer satisfaction is paramount for long-term success. With Alwajeez Tech’s ERP software, manufacturers can ensure that products are delivered on time, in the right quantities, and at the desired quality. The software’s real-time tracking of production, inventory, and orders helps in improving customer satisfaction by ensuring transparency and reducing delays in the supply chain.

7. Gain Competitive Advantage with Chemical ERP

The chemical industry is highly competitive, and companies that can streamline their operations and improve efficiency have a distinct advantage. By implementing Alwajeez Tech ERP for chemical companies, manufacturers can gain insights into production and supply chain processes, allowing them to make faster, data-driven decisions. This results in a competitive advantage that allows companies to stay ahead of market demands and industry trends.

8. Improve Supply Chain Management for Chemicals

A robust supply chain is essential for the smooth operation of a chemical manufacturing company. With Alwajeez Tech chemical manufacturing software, manufacturers can track raw material procurement, production schedules, and distribution, allowing them to respond quickly to supply chain disruptions. The software enables real-time updates, improving collaboration with suppliers and distributors and improving supply chain management for chemicals.

9. Streamline Chemical Production Processes

Chemical production processes involve numerous stages that require precise coordination, such as formulation, blending, packaging, and distribution. Alwajeez Tech ERP for chemical plants allows manufacturers to streamline production by automating workflows, minimizing bottlenecks, and ensuring that every step is optimized. This leads to greater streamlining of chemical production processes and ensures that production runs smoothly and efficiently.

10. Increase Chemical Production Visibility

Visibility into the production process is essential for identifying bottlenecks, inefficiencies, and areas for improvement. With Alwajeez Tech chemical ERP, manufacturers gain complete visibility into all aspects of production, from raw material procurement to finished goods delivery. This increased chemical production visibility helps companies make informed decisions and improve overall operational performance.

How Alwajeez Tech ERP Enhances Chemical Manufacturing

Customization for the Chemical Industry

Alwajeez Tech has developed chemical ERP software specifically tailored to meet the unique needs of the chemical manufacturing sector. The software is highly customizable, allowing companies to adapt it to their specific workflows, regulatory requirements, and production processes.

Integration with Other Systems

Alwajeez Tech ERP integrates seamlessly with other systems used in the chemical industry, such as manufacturing execution systems (MES), laboratory information management systems (LIMS), and third-party logistics systems. This integration ensures a smooth flow of data across the organization, reducing the risk of errors and improving operational efficiency.

Scalability for Growing Businesses

Whether you’re a small, medium, or large chemical manufacturing company, Alwajeez Tech ERP can scale to fit your needs. As your business grows, the ERP system can handle increased production volumes, complex supply chains, and expanded customer bases without compromising performance or functionality.

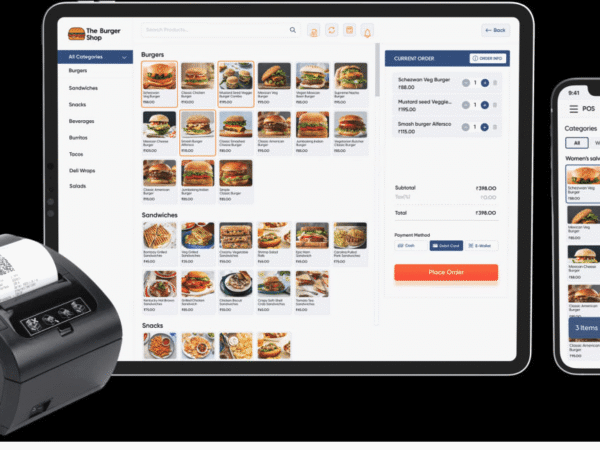

Cloud-Based Solutions for Flexibility

Alwajeez Tech offers cloud-based chemical ERP solutions, providing flexibility, mobility, and accessibility. With cloud deployment, companies can access the system from anywhere, ensuring that managers and teams have real-time data at their fingertips to make critical decisions.

Advanced Analytics and Reporting

One of the standout features of Alwajeez Tech chemical ERP is its advanced analytics and reporting capabilities. With detailed dashboards, custom reports, and data visualization tools, manufacturers can analyze their operations, identify trends, and make data-driven decisions to improve efficiency and reduce costs.

Why Choose Alwajeez Tech ERP for Your Chemical Company?

Choosing the right ERP software for your chemical manufacturing company is a critical decision. Alwajeez Tech ERP for chemicals offers a comprehensive suite of features designed to meet the unique challenges faced by chemical manufacturers. Some key reasons to choose Alwajeez Tech include:

- Industry-Specific Solutions: Tailored specifically for the chemical industry, Alwajeez Tech ERP meets the unique needs of chemical manufacturers.

- Scalability: The software is scalable, ensuring that it grows with your business.

- Customizability: Alwajeez Tech ERP can be customized to fit your company’s specific workflows.

- Cloud-Based Flexibility: Access the system from anywhere with cloud-based deployment.

- Advanced Analytics: Make data-driven decisions with comprehensive analytics and reporting tools.

In the highly competitive and complex world of chemical manufacturing, Alwajeez Tech ERP for chemical companies provides the tools needed to streamline production, improve quality control, enhance inventory management, and boost sales. By choosing Alwajeez Tech ERP for the chemical industry, companies can experience increased efficiency, reduced costs, and improved customer satisfaction.

If you’re looking to optimize your chemical manufacturing operations, reduce costs, and enhance productivity, consider contacting Alwajeez Tech for chemical ERP. Experience how Alwajeez Tech chemical manufacturing software can transform your business and provide a significant competitive advantage.

then 'Add to home screen'

then 'Add to home screen' then 'Add to home screen'

then 'Add to home screen'